Farm to Table

Step 1: Seed

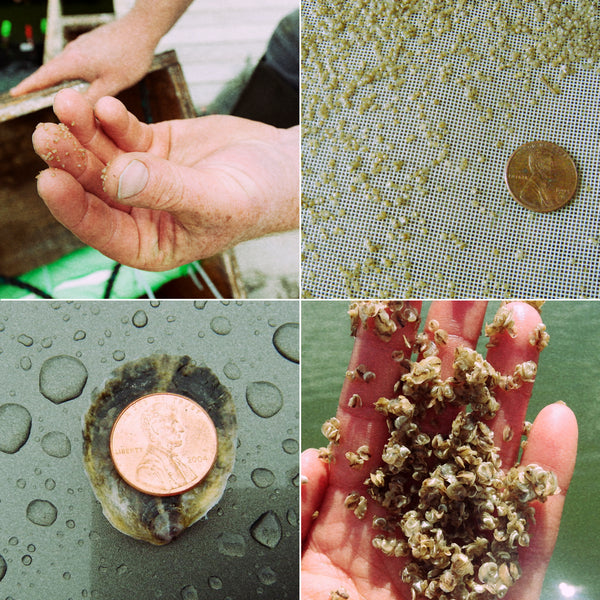

Late spring we receive tiny oysters (1.5mm), known as seed, from hatcheries around the northeast coast. A package with 1 million oysters will weigh roughly two pounds. Eighteen months later, when they reach market size, the same number could weigh up to eighty thousand pounds. Upon receiving seed, these babies are immediately put into our upweller system for the nursery phase of growing.

Step 2: Upweller

Our floating upweller system, also known as a “FLUPSY”, is a dock that contains a trough which holds mesh bottomed silos and in turn hold seed. Constant water flows up through the mesh to the youngsters and they thrive in this rich environment. A water pump helps the continuation of nutrient water, oxygen flow and removal of waste. Oysters feed on the algae in the water and can double their size in just one day.

Step 3: Grow Bags

Merry owns close to 10,000 different size plastic mesh bags that range in mesh size from 4 mm. to 6 mm. to 23 mm. The faster growing animals that have been graded from the upweller, are ready to move into 4 mm. mesh bags. Throughout the season the oysters are transferred to larger mesh to increase water flow. Roughly 1,200 oysters are measured to go in a single bag. In one day, typically 250,000 oysters are put out in bags and cages.

Step 4: Cages

To create maximum water flow, bottom cages are specifically spaced across a section of our lease. They sit on legs which ensure the oysters are off the mud during this phase of growing. Cages are specifically designed to hold eight mesh bags. Fouling organisms tend to grow on the bags so maintenance, like flipping and shaking, is frequently required.

Step 5: Bottom Plant

Once the seed is about 1.5” it is ready to be planted on the floor of the Bay. The seed is poured from the mesh bags to totes and spread across a section of the Merry lease. As the oysters sit on the bottom of the Bay they will continue to grow, adding shell and healthy weight. They become dormant in the winter when the water temperature (38f) and food levels drop. Come spring, when the water in the Bay begins to warm, they start steadily feeding and filtering again. Once the majority of oysters look to be market size, 3 inches from dorsal to ventral, the harvesting begins.

Step 6: Drag, Bag, Market

A few days a month, Duxbury has tides that allow us to hand pick oysters from our grant, but most days we harvest using a dredge that drags behind the boat. The harvested oysters are brought to the processing site and culled. Size, weight, and shape are all considered when sorting through these plump prawns. The marketable oysters are put into 100 count bags and put on ice or refrigerated until delivery. Merry Oyster’s refrigerated van makes the trek to the fish pier in Boston where Legal Sea Foods then distributes the bags across it’s 35 restaurants. If you find yourself in a Legal Sea Foods, be sure to try Merry Oysters and enjoy a taste of Duxbury Bay. You can now purchase our quality oysters online during the months containing the letter "R". Be sure to check out our online shop for more information!